You’re looking for an industrial robot… but which type of robot should you get?

There are so many different robot types to choose from. The best one for you will depend on how you categorize them and what applications you are considering.

Robots are very flexible compared to other types of automation, which tend to have a very narrow range of suitable applications. Even so, different types of robots are still better suited to particular tasks.

One way to categorize industrial robots is to split them into their basic types.

Here is a quick guide to the 7 types of robots that you might need…

What You Might Not Realize About Robot Types

Like many manufacturers, you might just be thinking, “We need to add a robot to our operations.”

It’s definitely a good idea to improve your processes with an industrial robot. But, saying you will just add “a robot” is a bit like saying that you need to add “a new CNC machine” or “a new worker.” It’s not specific enough to make the best decision about the right machine for you.

The differences between robot types can be quite significant. It helps when you understand these differences.

How Many Different Types of Robots Are There?

There are various ways to categorize robots. As a result, there are dozens — or perhaps even hundreds — of different types of robots.

One common way to categorize robots is by their sector:

- Industrial robots —These are robots used in industrial settings, such as in manufacturing. You’re most likely to be interested in industrial robots, so they are the primary focus of this article.

- Service robots —These are robots that have direct human contact. They are used in fields such as health and retail. Service robotics is still a developing field.

- Logistics robots —These are used for moving around products but not for manufacturing products themselves. You might use some of these in a manufacturing business.

- Educational robots —These are used to improve learning in educational settings.

There are crossovers between some of these categories. Plus, each category will have subcategories.

Which type of robots are most useful for you as a manufacturer?

It makes the most sense to learn about the types of robot you will actually use! For that reason, let’s focus on industrial robots…

7 Types of Robots Every Manufacturer Should Know About

A common and helpful way to compare different industrial robots is to split them into the following 7 types.

While some robots won’t fit neatly into these categories, this list is a good start.

The 7 types of robots are:

1. 6 Degree of Freedom Industrial Manipulator

The most common type of industrial robot you will see is a 6 Degree of Freedom (DoF) manipulator. As the name suggests, these have 6 active joints, usually rotational.

You can apply a 6 DoF robot to a vast range of tasks. They are very flexible and come in a range of sizes and other properties.

2. SCARA Robot

Selective Compliance Articulated/Assembly Robots (SCARA)are often used for detailed tasks like assembly, pick and place, and engraving.

A distinguishing feature of SCARA robots is their “selective compliance” in the Z-axis, which gives them flexibility for certain assembly tasks.

3. Delta Robot

Delta robots are often used for high-speed pick and place tasks, such as sorting products on fast-moving conveyors.

Because of their parallel kinematic structure, delta robotshave a complex workspacecompared to 6 DoF manipulators.

4. Palletizing Robot

Unlike the previous robot types,palletizing robotsare categorized by their core application area — palletizing.

The major mechanical difference with palletizing robots is that they usually have only 5 Degrees of Freedom, the final DoF is parallel to the floor, and two of their joints are coupled for added strength.

5. Redundant Manipulator

A redundant robot is one with more DoFs than it needs for a given task. An example is a 7 DoF industrial manipulator.

Common advantages of using a redundant manipulator include the elimination ofrobot singularities, higher system stiffness, and a better distribution of loads.

6. Collaborative Robot

A collaborative robot (or cobot) is a special type of robot designed to operate safely around human workers without needing extra sensing or safety measures.

Cobots have risen to popularity over the past decade as they tend to be easy to use and are well-suited to new robot users.

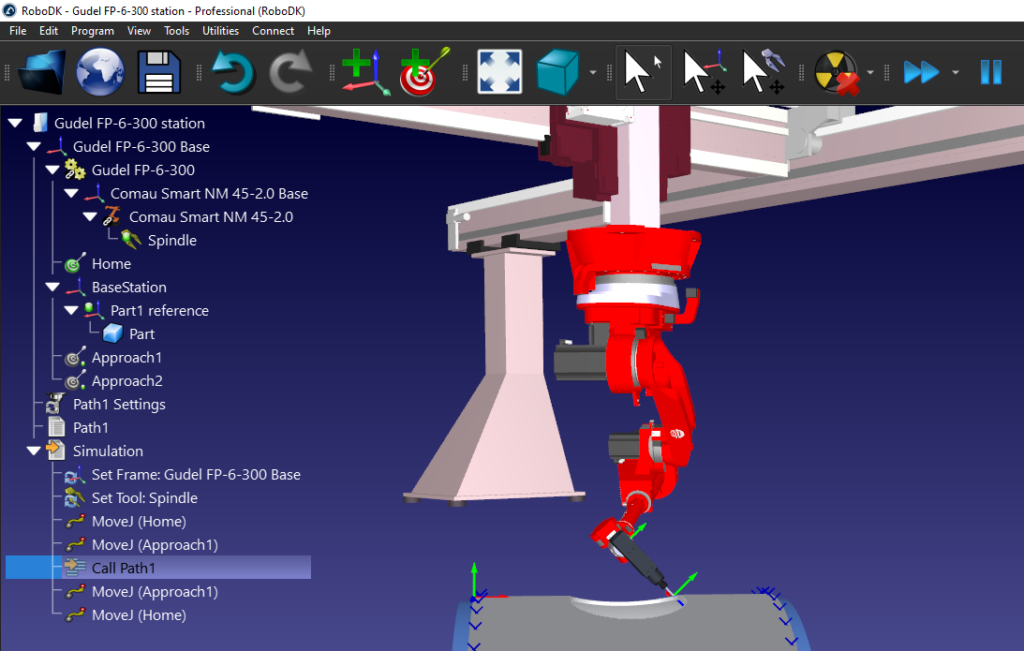

7. Gantry Robot

乍一看,龙门robots look more like overhead cranes. The difference is that you can program and control them in the same way as other industrial robots.

People often use gantry robots in collaboration with 6 DoF manipulators, with the manipulator hanging from above.

Which Industrial Robot Types Should You Consider?

The key to finding the right industrial robot for you is to get one that suits your chosen application.

Identify which tasks you want to improve with robotic automation. Then, go out and find robots that could suit those tasks.

Also, try to think long term. It’s possible that you won’t need to automate this particular task in the future. If it’s easy torepurpose your robot, this can be a tremendous benefit. For example, you can apply a 6 DoF manipulator to a wider range of tasks than, say, a palletizing robot.

How to Program Any Robot Type Quickly and Easily

Whatever type of robot you choose, you need to program it.

Choose a robot programming software that is compatible with many different robot types. This will help you get the most from your robot investment for years to come.

Steer clear of robot programming systems that are only compatible with a particular robot type or manufacturer.

RoboDK is compatible with many robot types and hundreds of robot models.你可以下载一个免2022世界杯国家队名单费的RoboDK下来load page.

What robot type do you most think would suit your needs?Tell us in the comments below or join the discussion onLinkedIn,Twitter,Facebook,Instagram, or inthe RoboDK Forum.. Also, check out our extensive video collection and subscribeto the RoboDK YouTube Channel